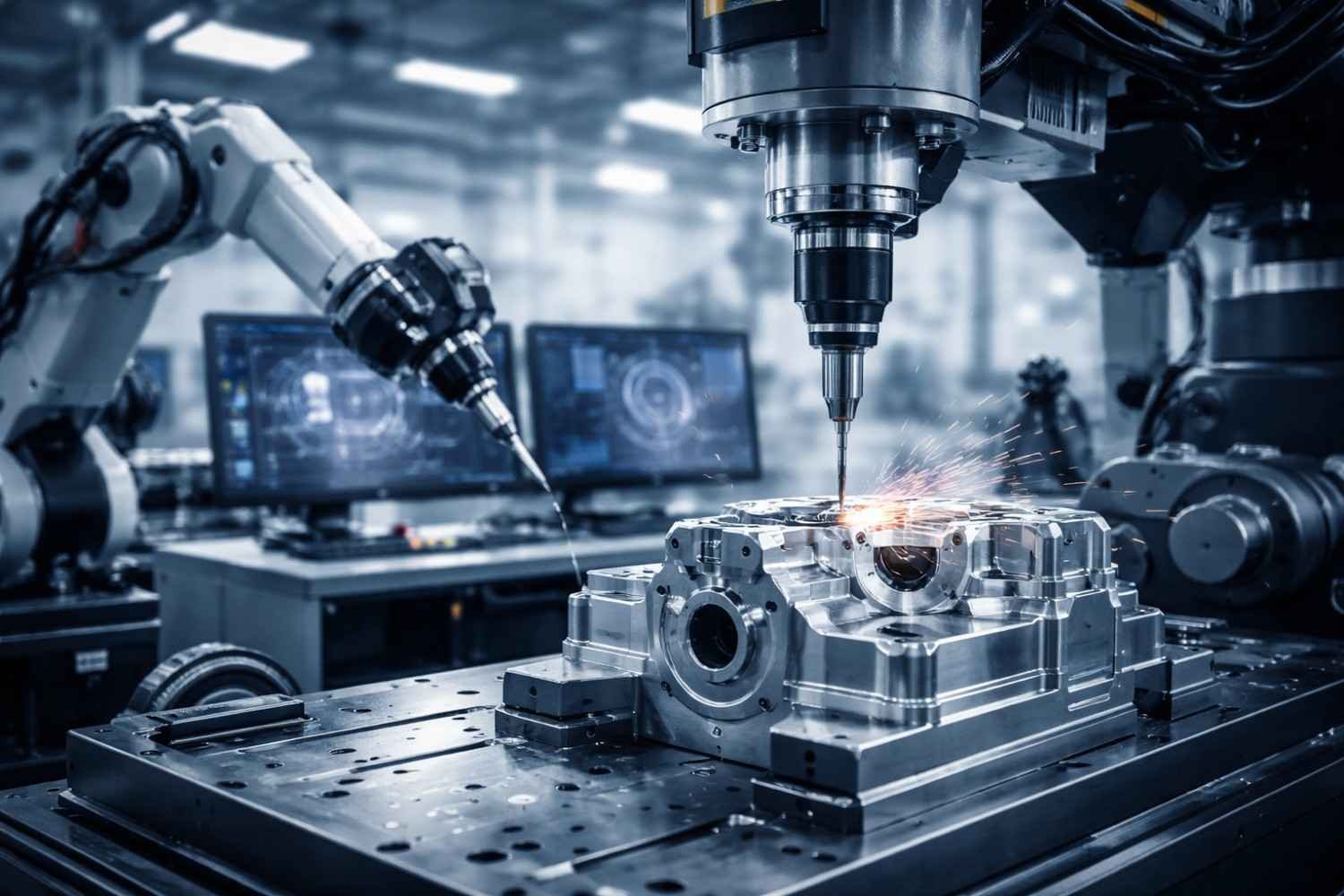

Material failure is the nightmare of every industrial engineer and project manager. A single cracked seal, a snapped belt, or a degraded hose can halt an entire production line, leading to costly downtime and potential safety hazards. In industrial manufacturing, selecting the right materials is not merely a box-checking exercise; it is a foundational decision that dictates the longevity, efficiency, and safety of your operation.

Key Properties of Flexible Materials

Flexibility is often misunderstood as simply “softness.” In an industrial context, flexibility refers to a material’s ability to deform under stress and return to its original shape without sustaining damage. When evaluating flexible materials, two specific metrics stand out: tensile strength and elastic recovery.

Tensile Strength and Elongation

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. For flexible components like conveyor belts or hydraulic hoses, high tensile strength is non-negotiable. However, strength must be balanced with elongation—the percentage a material can stretch before failure.

A material with high tensile strength but low elongation is brittle. For dynamic applications, you need a material that offers a high modulus of elasticity, allowing it to endure significant stretching forces while maintaining structural integrity.

Elastic Recovery

It is not enough for a material to stretch; it must also bounce back. Elastic recovery refers to a material’s ability to return to its original dimensions after the load is removed.

In applications involving seals and gaskets, poor elastic recovery results in compression set. This happens when a material permanently deforms after being compressed for a long period, eventually leading to leaks. High-quality flexible materials exhibit near-perfect elastic recovery, ensuring that seals remain tight and moving parts function smoothly over thousands of cycles.

Understanding Durability in Harsh Environments

Durability is the measure of a material’s lifespan under the specific conditions of its environment. In industrial settings, this usually means resistance to three primary aggressors: chemicals, temperature extremes, and mechanical wear.

Chemical Resistance

Industrial environments are rarely clean. Components are frequently exposed to oils, solvents, acids, and cleaning agents. A material that swells, cracks, or dissolves upon contact with these substances is a liability.

When selecting materials, you must review compatibility charts against every chemical the material might encounter. For instance, natural rubber offers excellent mechanical properties but degrades quickly when exposed to petroleum-based oils. In such cases, synthetic alternatives are superior choices due to their hydrocarbon resistance.

Temperature Resilience

Heat accelerates degradation, causing materials to harden and crack, while extreme cold can make flexible materials brittle and prone to shattering.

“Service temperature range” is a critical specification. You need materials that maintain their flexibility across the entire operating spectrum. Silicones, for example, are renowned for their ability to remain flexible at temperatures as low as -60°C and as high as 230°C, making them ideal for everything from cryogenic seals to high-heat automotive gaskets.

Resistance to Mechanical Wear

Mechanical wear includes abrasion, fatigue, and impact.

- Abrasion: Occurs when materials rub against other surfaces. Polyurethane is often the gold standard here, outlasting rubber and plastics in high-friction environments.

- Fatigue: Results from repeated loading and unloading. Materials with high fatigue resistance can withstand millions of flex cycles without developing stress cracks.

- Impact: The ability to absorb shock without fracturing.

Top-Performing Materials for Industry

While new compounds are developed regularly, a few material families consistently perform well in applications requiring both flexibility and durability.

Advanced Polymers (TPUs and TPEs)

Thermoplastic Polyurethanes (TPU) and Thermoplastic Elastomers (TPE) bridge the gap between rubber and plastic. They offer the elasticity of rubber with the processing advantages of plastic. TPUs are exceptionally tough, offering high abrasion resistance and load-bearing capacity, making them perfect for industrial caster wheels, power tools, and drive belts.

Synthetic Rubbers and Silicones

Synthetic rubbers like Neoprene and EPDM remain industry staples due to their weather resistance and durability. For more demanding applications, silicone rubber offers unmatched thermal stability and chemical inertness, which is why it is heavily used in food processing and pharmaceutical manufacturing.

Flexible Composites and Sheeting

Sometimes, a single material cannot provide all the necessary properties. This is where composites and specialized sheeting come into play. Reinforced rubber sheeting, for example, often incorporates fabric inserts (like nylon or cotton) to drastically increase tensile strength while retaining the flexibility of the rubber matrix. This type of material is essential for making durable diaphragms, gaskets, and protective skirting that must endure high pressure without tearing.

Practical Considerations: Cost vs. Longevity

The initial price tag of a material is rarely its true cost. Cheaper materials often lead to higher long-term expenses due to frequent replacements, maintenance labor, and production downtime.

Calculating Lifecycle Value

When evaluating costs, consider the Total Cost of Ownership (TCO). A premium fluoroelastomer gasket might cost five times more than a standard rubber one. However, if the standard gasket needs replacement every month while the premium one lasts a year, the premium option is significantly cheaper—not just in parts, but in the labor savings and reduced downtime.

Maintenance and Ease of Repair

Select materials that align with your maintenance capabilities. Some materials provide visual indicators of wear (like colored layers that reveal themselves as the top layer abrades), allowing for predictive maintenance. Additionally, consider how easy it is to patch or repair the material on-site versus replacing the entire component.

Future Trends in Industrial Materials

The landscape of industrial materials is shifting toward sustainability and intelligence.

Sustainable Alternatives

Manufacturers are increasingly seeking bio-based polymers and recyclable elastomers to reduce their environmental footprint. Innovations in bio-TPUs are providing performance metrics that rival traditional petroleum-based plastics, allowing companies to meet sustainability goals without sacrificing durability.

Smart Materials

The integration of Industry 4.0 is leading to the development of “smart” materials. These include self-healing polymers that can repair micro-cracks autonomously and materials embedded with sensors to monitor strain and temperature in real-time. While still emerging, these technologies promise to revolutionize predictive maintenance by allowing materials to “communicate” their health status before failure occurs.

Conclusion

Now that you have a better understanding of the various factors that contribute to material durability, you can make more informed decisions when selecting materials for your projects. Remember to consider environmental conditions, loading and stress levels, as well as potential failure mechanisms. With advancements in technology and the development of smart materials, the future looks bright for even more durable and resilient materials.