Manufacturing has undergone a quiet revolution. For centuries, the quality of a product depended entirely on the steady hand and sharp eye of a skilled artisan. A master carpenter could craft a beautiful chair, but the second chair might have a leg a millimeter shorter than the first. While that variance gives successful craft pieces their charm, it is a liability in industrial production. Today, the margin for error in sectors like aerospace, medical devices, and automotive manufacturing is effectively zero.

The Blueprint of Perfection: Computer-Aided Design (CAD)

Long before a piece of metal is cut or a sheet of plastic is molded, the battle for accuracy is won in the digital realm. Computer-Aided Design (CAD) has fundamentally changed how products are conceived. In the past, drafting was a manual process subject to interpretation and human error during the translation from paper to machine.

CAD eliminates this ambiguity. It creates a digital twin of the final product—a mathematical representation that is exact. Engineers can zoom in to the micron level to adjust tolerances, ensuring that parts will fit together perfectly before physical materials are ever touched.

Simulation and Stress Testing

The power of CAD extends beyond geometry. Modern software allows engineers to run complex simulations on these digital models. They can test how a material will expand under heat, how it will bend under pressure, or how airflow will interact with a surface.

By solving these problems in a virtual environment, manufacturers avoid the “trial and error” phase on the factory floor. The first physical prototype produced is often near-production quality because the digital blueprint has already been perfected. This direct link between the digital file and the manufacturing equipment ensures that the intent of the design is preserved with 100% fidelity during production.

The Unwavering Hand of Automation and Robotics

Human operators, no matter how skilled, have physical limitations. Fatigue sets in, attention wavers, and dexterity varies from person to person (and from Monday morning to Friday afternoon). Automation removes these biological variables from the equation.

Robotic arms and automated assembly lines perform tasks with a level of repeatability that humans cannot match. If a robot is programmed to spot-weld a car chassis at a specific coordinate with a specific amount of pressure, it will do so for the first car and the ten-thousandth car without a fraction of deviation.

CNC Machining

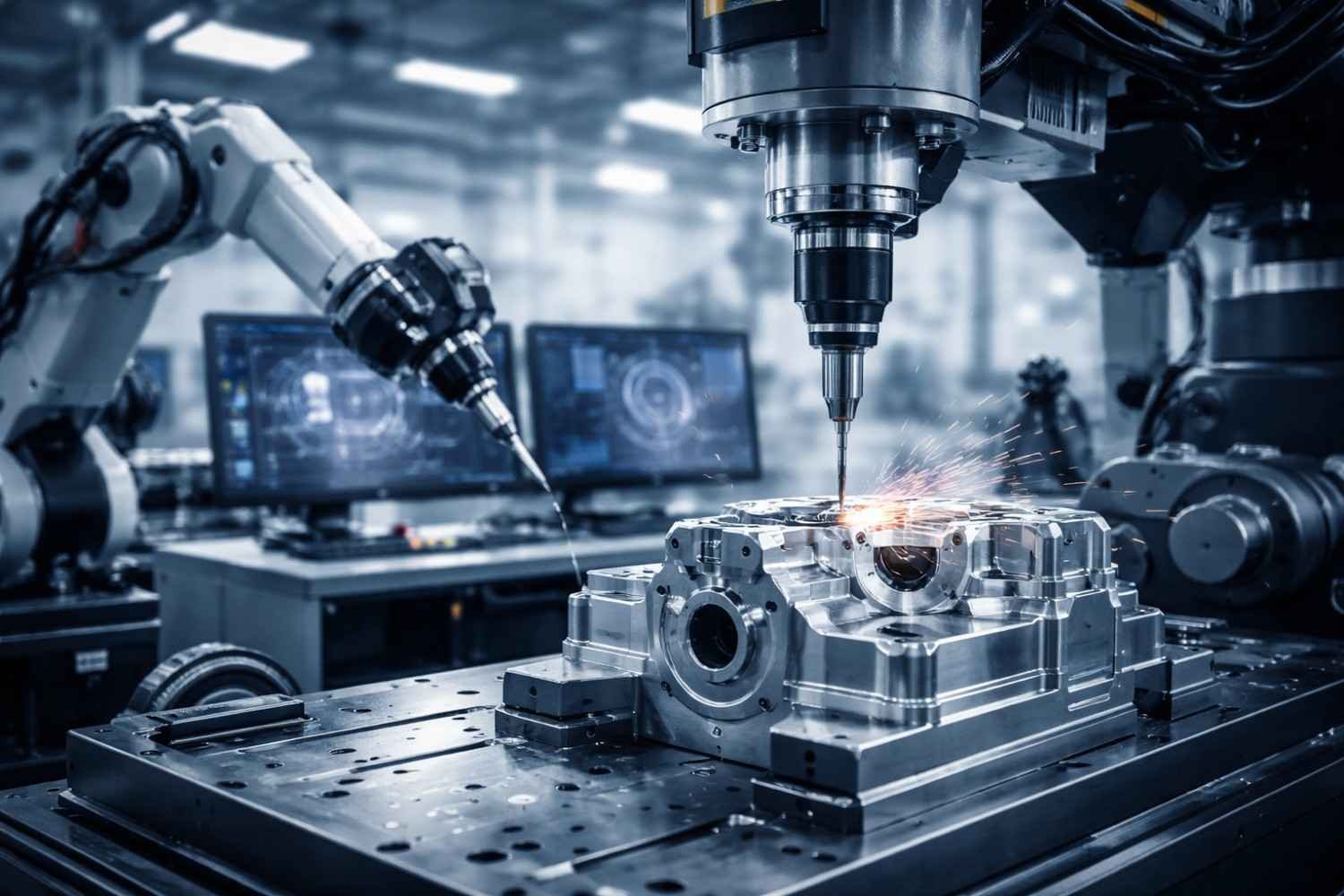

Computer Numerical Control (CNC) machining is the backbone of this automated precision. CNC machines take the data directly from CAD files and control machine tools—lathes, mills, and grinders—via computer software.

Because the machine is following a strict set of coded instructions (G-code), the resulting component is mathematically consistent with the design. This allows for complex geometries that would be difficult or impossible to machine manually. The machine moves along multiple axes simultaneously, carving out intricate shapes with rigid consistency, ensuring that every batch of parts is identical to the last.

Reducing Human Error Through Advanced Tooling

While automation handles the heavy lifting, advanced tooling handles the fine details. The reduction of human interaction in the actual cutting and shaping process has been the single biggest driver of improved accuracy.

In traditional fabrication, a worker might guide a piece of sheet metal through a press or a saw. Even with guides and jigs, the worker’s grip strength or viewing angle could introduce slight imperfections. Modern fabrication removes the operator from the immediate cutting zone, replacing them with computer-guided energy.

Techniques like precise laser cutting utilize a focused beam of light to melt, burn, or vaporize material. The laser is driven by a computer, tracing patterns with an accuracy tolerance often measured in thousandths of an inch. Because there is no physical cutting edge to wear down or dull over time, the cut quality remains consistent from the first minute of the shift to the last. The thermal distortion is minimal, and the edges are clean, often requiring no secondary finishing.

This level of control prevents the “drift” often seen in manual manufacturing, where tools degrade or operators get tired, leading to parts that slowly drift out of spec as the day goes on.

Scaling Up: Mass Customization and Consistency

Historically, there was a trade-off between volume and variety. You could have high consistency if you made millions of the same item (mass production), or you could have high customization if you made items one by one (craft production), but the latter often lacked consistency.

Modern fabrication has broken this dichotomy. Because machines are driven by software, changing a product’s specifications does not necessarily require a complete retooling of the factory. A file can be updated, and the machine adapts instantly.

The Agility of Software

This capability allows for mass customization—producing unique, custom-tailored products with mass-production efficiency and consistency. For example, in the medical field, implants can be machined to fit a specific patient’s anatomy based on MRI scans. The fabrication equipment treats this unique job with the same speed and precision as a standard part.

This scalability ensures that accuracy isn’t lost when production ramps up. Whether a factory is producing ten units or ten thousand, the digital instructions remain the same, ensuring that the scaling process doesn’t dilute the quality of the output.

Quality Control and Real-Time Monitoring Systems

Even with the best machinery, variables can occur—a tool might chip, or raw material might have an inconsistency. In the past, quality control (QC) was a reactive process. Inspectors would check random samples at the end of the production line. If a defect were found, the entire batch might have to be scrapped, leading to massive waste and cost.

Modern fabrication integrates QC directly into the manufacturing process through the Industrial Internet of Things (IIoT). Sensors embedded in machines monitor vibration, temperature, and power consumption in real-time.

Vision Systems

Advanced vision systems use high-resolution cameras and machine learning algorithms to inspect parts as they are being made. These systems can detect surface flaws, incorrect dimensions, or assembly errors that are invisible to the naked human eye.

If a deviation is detected, the system can instantly halt the machine or automatically adjust parameters to correct the issue before the next part is made. This creates a closed feedback loop. The machinery is constantly “listening” to the process and self-correcting. The result is a dramatic reduction in defective parts reaching the customer, effectively guaranteeing that what ships out the door meets the rigorous standards set during the design phase.

Conclusion

The trajectory of manufacturing is clear: the gap between design and reality is closing. Modern fabrication has transformed accuracy from a goal into a guarantee. By integrating digital design, automated execution, and intelligent monitoring, manufacturers have built a system where consistency is the default state.